Large-scale industrial welding is slow, and high quality is difficult to maintain. Any changes or developments in a product mean that an entire new jig has to be designed, manufactured, and calibrated. This long and inefficient process means precious time is often wasted as machines are not in use.

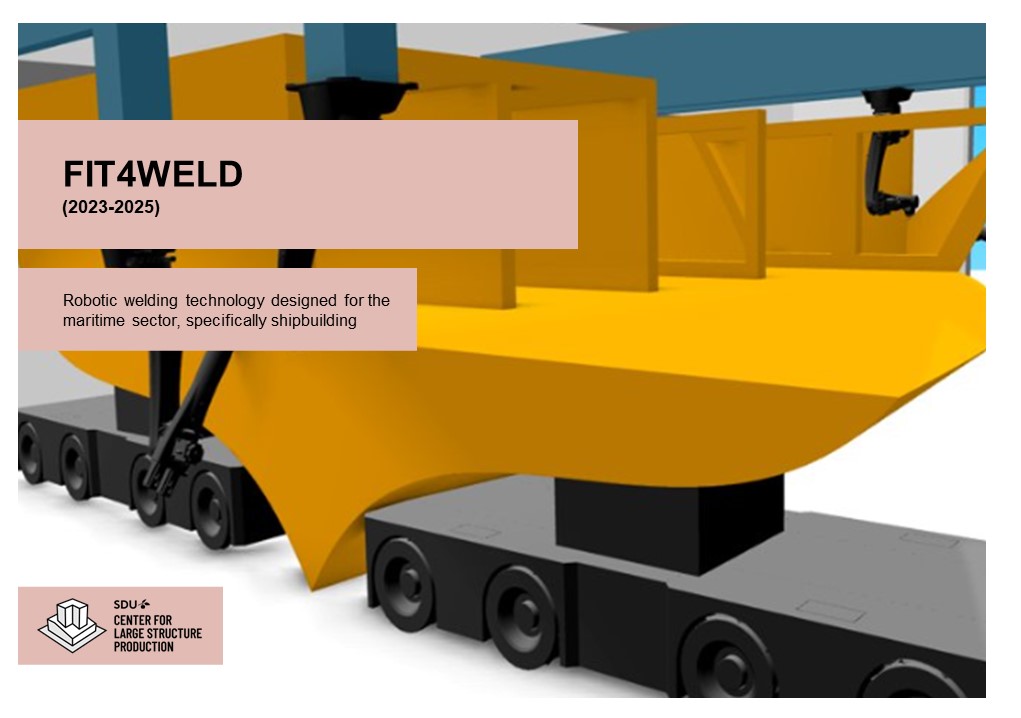

The Fit4Weld project looks to solve this. In collaboration with our partners, the Large Structure Production Center is developing the Fit4Weld welding cell. Self-adjustable and highly flexible, with the use of a self-adjustable jig system, long machine down-times will be avoided, making industrial welding quicker, more flexible, and more efficient.

With an easily controlled user interface, the robotized cell allows for more designs and products in less time.